how to use a water jet cutter

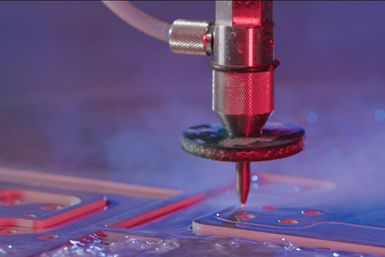

The high pressure of the water jet cuts. In this process pressurizing pumps deliver high-pressure jets of water.

Machining 101 What Is Waterjet Cutting Modern Machine Shop

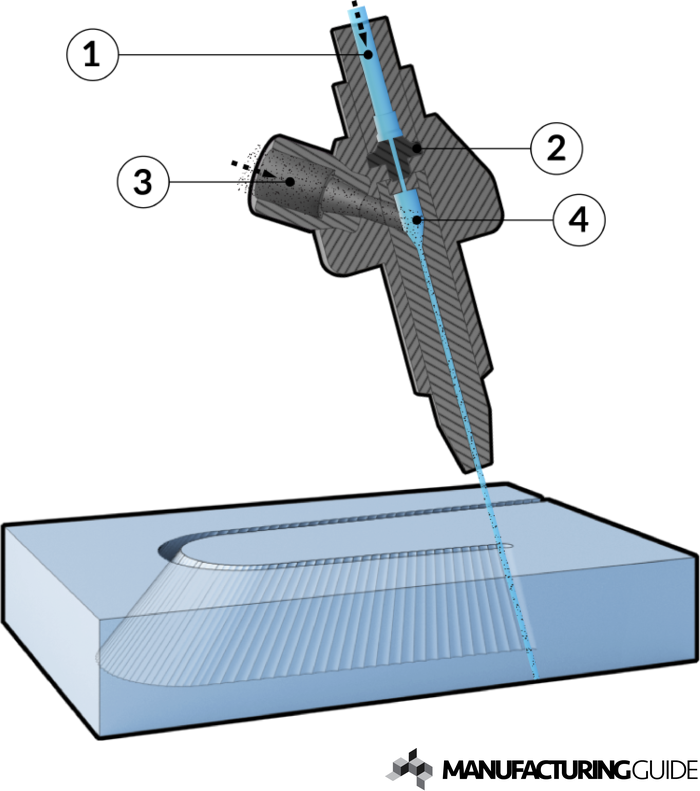

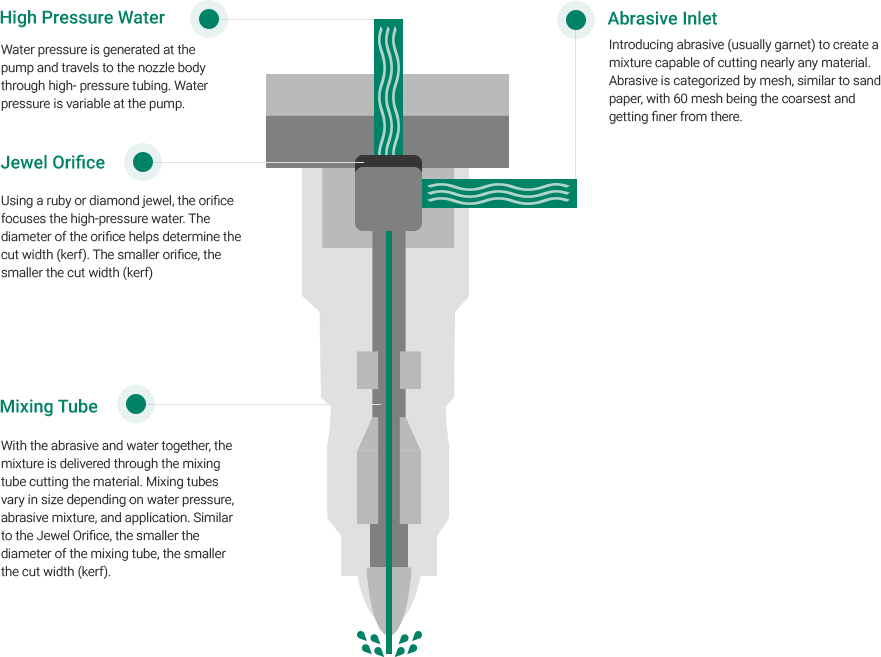

Using a ruby or diamond jewel the orifice focuses the high-pressure water.

. Yet its still industrial grade enough to CNC cut steel. Water jet cutting is used to create permanent name plates out of heavy metals. A water jet cutter is a device capable of cutting right into metal or other materials utilizing a jet of water at high speed rate and pressure.

In some cases the water is supplemented with. Industrial water jet cutting though is a non-thermal process. Stone can be cut using a water jet cutter to make a variety of carvings.

The main reasons for using water jet cutting are due to its precision removal of the need for finishing. The stones used for this purpose are made from various materials including marble granite limestone and more. A water jet cutter also known as a water jet or waterjet is an industrial tool capable of cutting a wide variety of materials using an extremely high-pressure jet of water or a mixture of water.

Tips for Your DIY Water Jet Cutter. The first small waterjet cutter in a compact package. The waterjet cutter can be used either.

In many different sectors including the metal and plastics processing industries the demand for processing with a water jet cutter. Aluminum waterjet cutting involves a cutting head that emits a high-pressure jet of water focused on the material that requires cutting. The smaller orifice the smaller the cut width kerf.

Stone can be cut using a water jet cutter to make a variety of carvings. I show the basics of what a w. Water cutters operate by pushing water out of a cutting head at extremely high speeds.

Water Jet Cutter advantages and application possibilities. Tips for Your DIY Water Jet Cutter. The smaller orifice the smaller the cut width kerf.

Water jet cutting is a kind of sheet metal fabrication process cutting nearly any type of material soft and hard. We should know that water jet cutters are efficient tools for cutting any kind of object because it is able to products a very sharp pressurized water that could cut things smoothly. Yes it is easy to cut stone using a waterjet and not only granite as a high-pressure waterjet cutter is ideal for cutting stone such as marble too.

I was getting a lot of questions about how the Flow Mach 500 waterjet works so I decided to answer all of them with this video. The diameter of the orifice helps determine the cut width kerf. The process is used to produce name plates signage and company logos.

The process is used to produce name plates signage and. It does not generate heat making it suitable for heat-sensitive materials. A waterjet cutter can deliver up to 30 kW of power within a fine high pressure waterjet at the size of a needle and can cut almost any material.

A water jet can cut stone up to 12.

Basics Of Waterjet Cutting Same Waterjet

How Waterjet Helped Nashville Designer Omax Waterjet

3d Abrasive Water Jet Cutting Of Flat Materials Find Suppliers Processes Material

What Is A Waterjet Cutting Machine

Fast Extreme Water Jet Cutter Machine Working Modern Technology Waterjet Cutting Compilation Youtube

Waterjet Cutting Process Benefits And Materials Explained Fractory

What Is Waterjet Cutting Technology And How Does It Work Techni Waterjet

Water Jet Cutter Inexpensive Water Jet Cutting Machine

Small Portable Water Jet Cutter For Sale Used Waterjet Machines Systems Waterjet Glass Cutting Waterjet Machine System Machineused Machine Aliexpress

Water Jet Cutting Cost Effective Contract Cutting

The Process Of Water Jet Cutting Explained Performance Waterjet Pwj

Water Jet Cutting Machine Water Jet Cutting System

Waterjet Cutting Process Benefits And Materials Explained Fractory

Preparing A Fabricator S Game Plan For Jumping Into Waterjet Cutting

X3 Waterjet Cutter Aks Cutting Systems

All About Waterjet Cutting Services

An Engineer S Guide To Waterjet Cutting Engineering Com